Lean Manufacturing Services

QUALITY AND OPERATIONS

PROYECTS / INTERIM MANAGEMENT

AD HOC TRAINING

LEAN PROCESS DIGITALIZATION

Lean Manufacturing:

Quality and Operations

Our methodology focuses on identifying and eliminating process-related waste points, with the goal of improving customer satisfaction and increasing profitability. Through the implementation of Lean tools, we analyse and improve every stage of production to minimize failures, reduce costs, and optimize key service indicators.

At Quality&Operations, we know that the poor-quality associated costs are one of the biggest sources of inefficiency in companies. That’s why we optimize processes to reduce scrap (non-value-added waste), process defects, and the number of complaints, ensuring a significant improvement in quality indexes.

- Scrap ratios and process defects improvement

We reduce and eliminate process failure modes and improve quality at production.

- Customer claim reduction

We minimize customer complaints through proactive quality management.

- Quality performance improvement

Key Process Indicator like Process PPM´s or First Pass Yield Optimization, as well as customer satisfaction, driving operational efficiency.

How do we do it?

With our comprehensive approach, your company not only improves quality, but also increases its competitiveness by reducing the costs associated with poor quality:

- Implementation of required indicators for process quality management

- Management of containment actions and firewall plans.

- Implementation of effective control plans and SPC methods.

- Implementation of control tools, error proofing devices, and poka yokes.

- Use of appropriate tools and team training: A3/8D, QRQC, Six Sigma, Ishikawa, 5 Why's...

- Process quality document management: PFMEA, control plan, control guidelines, instructions, etc.

By applying proven Lean tools, we optimize any process stage of any activity’s to maximize the value flow and minimize inefficiencies.

VSM – 5’S – SMED – TPM – MUDA – TWI – ANDON / POKA YOKE – KANBAN – VISUAL MANAGEMENT

Moreover, It creates a continuous improvement culture that boost long-term productivity.

- Efficiency Improvement

We optimize the use of time, resources, and energy, resulting in reduced operating costs.

- Elimination of waste

We identify and eliminate activities that do not add value, such as overproduction, waiting times, and defects.

- Reduction of production costs

We increase profitability improving process flow, making them more agile and less expensive.

How do we do it?

We guarantee a positive and sustainable impact on your production processes, boosting your company to achieve operational excellence:

- Analysis of process stages, identifying bottlenecks and unnecessary waiting time, while balancing activities across the value chain.

- Implementation of PULL production systems based on end-customer demand.

- Lay-out Improvement and shopfloor re-organization according to process flow.

- Standardization of processes using the 5´S methodology.

- Implementation of SMED methodology to improve changeover time and eliminate unnecessary activities.

- Standardization of productive maintenance activities according to TPM methodology.

Through the integration of advanced tools and monitoring systems, we facilitate early identification of process deviations, enabling agile, well-informed decision-making tailored to market demands.

- Improve operational efficiency

We improve process performance across all operational areas, maximizing resource utilization.

- Safety, quality, cost, and delivery time

We ensure compliance with rigorous standards, maintaining high levels of safety and quality while optimizing costs and delivery times.

- Streamlined decision-making

We enable more effective management through access to accurate, real-time data that allows for a quick response to any deviation.

- Continuous Improvement Culture

We foster the creation of an environment where all members of the organization are engaged in the ongoing improvement process.

How do we do it?

We support companies to optimize their operations and establish the foundations for sustained growth through efficient and lean management:

- Definition of appropriate operational model, structure, and procedures.

- Implementation of required KPI´s to control productive operations.

- Deployment of “fast response” dynamics and problem escalation.

- Development of PDCA models and monitoring panels.

- Implementation of visual management on the shop floor.

We offer a comprehensive approach that ensures tangible improvement in organizational performance, contributing to the achievement of high standards and long-term value creation. This approach is materialized through:

- Implementation of management systems and support in the certification process:

Alignment with ISO 9001:2025; IATF 16949:2016, and ISO 14001:2015 standards enable companies to meet the highest quality standards and sustainability.

- Setting of quality systems to automotive customer specific requirements:

VDA 6.3, Ford, Daimler, JLR, Volkswagen, Volvo, etc.

- Implementation of integrated management systems for quality, environment, and safety

Facilitates cohesive and efficient management of all critical aspects of the organization.

How do we do it?

- Context of Organization's and the scope of the system definition.

- Definition of key and support processes within the organization, developing a proper process mapping.

- Analysis of risks and opportunities for each process.

- Creation of integrated dashboards.

- Development of an appropriate implementation plan for management system standards, tailored to customer needs.

Projects / Interim Management

Expert leadership to transform operations

-

Interim Management

for Plant Restructuring -

Optimizing the structure and performance of a plant demands specialized leadership and strategic management. At Quality&Operations, we offer an Interim Management service designed to boost operational efficiency through two key approaches:

- Interim Projects in Operational Areas

Imagine having an Operations Director, a Quality Manager, and a Continuous Improvement Facilitator implementing contracted projects on-site, while training the teams directly in the plant. That is exactly what we deliver to our clients: effective implementation and immediate impact on the organization.

- Operational Analysis and Restructuring

Detailed analysis of manufacturing plants, technical areas, and departments to detect inefficiencies, proposing strategic restructurings. These actions allow to improve process efficiency, resource optimization, cost reduction, and increase production capacity.

-

Project Management

– APQP -

Success in the industrialization of new products and process optimization depends on effective and structured management. Our comprehensive project management and APQP service (Advanced Product Quality Planning) ensures compliance with technical requirements, process optimization, and risk mitigation at every stage of production.

- Implementation of Production Lines and Cells

We define the most efficient layout, manage the installation and commissioning of machinery and tooling, and guarantee an optimized production process from the outset.

- First Sample Approval – PPAP

We manage the submission of first sample approval documentation (PPAP), ensuring compliance with the standards required by clients and regulatory bodies.

- First Sample Approval – PPAP

We ensure structured planning and rigorous control at every stage of the industrialization process:

- Definition and planning of the activities schedule.

- Manufacturing of prototypes, aligned with customer requirements, product specifications, and the capabilities of the production process.

- Design and validation of production processes, tooling, and control systems.

- Validation of products and processes, assuring its conformity and performance before start of production.

- Supplier Quality Development

-

Optimizing supplier quality is essential to ensure an efficient and a seamless supply chain. Part of our work involves the ongoing evaluation and monitoring of strategic suppliers to minimize rejections and maximize their performance.

- Development of critical suppliers or those with high rejection rates.

- Diagnosis and qualification of suppliers according to quality standards.

- Supplier Performance Assessment

- Documentation and standardization of quality criteria.

- Implementation and management of corrective actions.

- Application of preventive strategies to avoid non-conformities.

- Continuous review of supplier performance.

- Deployment of process controls to ensure stability.

- Management of non-conforming material and reduction of its economic impact.

-

Training and Development

in Operational Management -

Continuous training is key to boosting efficiency and improvement in industrial processes. At Quality&Operations, we collaborate with various institutions as specialized trainers, providing practical and applicable knowledge for the production environment.

- Quality Basics in production

- Training in Lean tools: 5S, SMED, TPM, VSM, TWI, Poka-Yoke.

- Problem-solving methodologies: A3 Model, 8D Model, Quality Circles.

- Process documentation: PFMEA, Control Plan, Operating Methods.

- Norms and standards: ISO 9001, ISO 14001, IATF 16949.

Optimizing the structure and performance of a plant demands specialized leadership and strategic management. At Quality&Operations, we offer an Interim Management service designed to boost operational efficiency through two key approaches:

- Interim Projects in Operational Areas

Imagine having an Operations Director, a Quality Manager, and a Continuous Improvement Facilitator implementing contracted projects on-site, while training the teams directly in the plant. That is exactly what we deliver to our clients: effective implementation and immediate impact on the organization.

- Operational Analysis and Restructuring

Detailed analysis of manufacturing plants, technical areas, and departments to detect inefficiencies, proposing strategic restructurings. These actions allow to improve process efficiency, resource optimization, cost reduction, and increase production capacity.

Success in the industrialization of new products and process optimization depends on effective and structured management. Our comprehensive project management and APQP service (Advanced Product Quality Planning) ensures compliance with technical requirements, process optimization, and risk mitigation at every stage of production.

- Implementation of Production Lines and Cells

We define the most efficient layout, manage the installation and commissioning of machinery and tooling, and guarantee an optimized production process from the outset.

- First Sample Approval – PPAP

We manage the submission of first sample approval documentation (PPAP), ensuring compliance with the standards required by clients and regulatory bodies.

- First Sample Approval – PPAP

We ensure structured planning and rigorous control at every stage of the industrialization process:

- Definition and planning of the activities schedule.

- Manufacturing of prototypes, aligned with customer requirements, product specifications, and the capabilities of the production process.

- Design and validation of production processes, tooling, and control systems.

- Validation of products and processes, assuring its conformity and performance before start of production.

Optimizing supplier quality is essential to ensure an efficient and a seamless supply chain. Part of our work involves the ongoing evaluation and monitoring of strategic suppliers to minimize rejections and maximize their performance.

- Development of critical suppliers or those with high rejection rates.

- Diagnosis and qualification of suppliers according to quality standards.

- Supplier Performance Assessment

- Documentation and standardization of quality criteria.

- Implementation and management of corrective actions.

- Application of preventive strategies to avoid non-conformities.

- Continuous review of supplier performance.

- Deployment of process controls to ensure stability.

- Management of non-conforming material and reduction of its economic impact.

Continuous training is key to boosting efficiency and improvement in industrial processes. At Quality&Operations, we collaborate with various institutions as specialized trainers, providing practical and applicable knowledge for the production environment.

- Quality Basics in production

- Training in Lean tools: 5S, SMED, TPM, VSM, TWI, Poka-Yoke.

- Problem-solving methodologies: A3 Model, 8D Model, Quality Circles.

- Process documentation: PFMEA, Control Plan, Operating Methods.

- Norms and standards: ISO 9001, ISO 14001, IATF 16949.

Ad Hoc Training and Coaching for Team Development

Our method focuses on identifying and eliminating sources of waste related to quality, aiming to enhance customer satisfaction and increase profitability. By implementing Lean tools, we analyse and improve each stage of production to minimize errors, reduce costs, and optimize key service indicators.

We develop company talent

and foster teamwork

- Operations in a manufacturing plant: “The basketball plant”

- Implementation of PDCA sessions and Kaizen groups.

- Development of a continuous improvement culture within the organization.

-

Enhancement of participation,

communication, and workplace environment. - Increase of the improvement pace.

Professional coaching

in production areas

- Definition Role or function description within the organization.

- Team Skills assessment.

- Identification of improvement areas and development plans.

- Support throughout the process of professional performance improvement.

Digitization of

Lean Processes

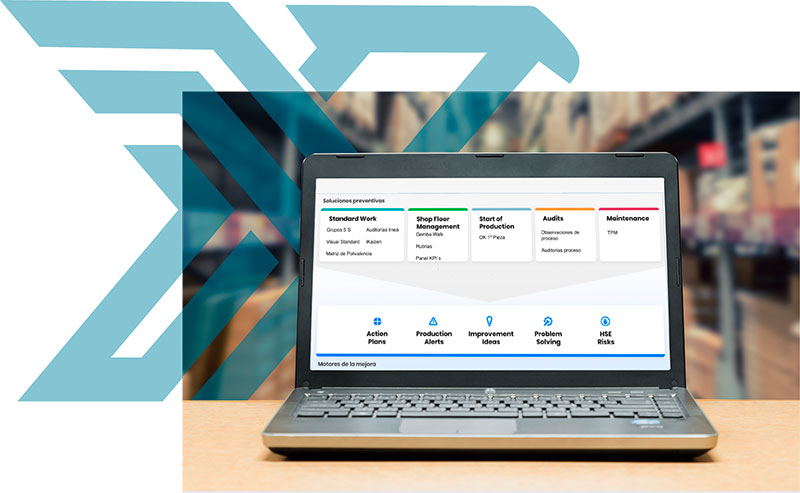

As an official partner of mlean, at Quality & Operations we strive to develop a zero-waste culture, where everything works right from the start, optimizing operations and fostering a continuous improvement mindset.

Production System (mPS)

The mlean Production System (mPS) is a comprehensive modular software, available for web and mobile use, based on lean manufacturing principles. It incorporates the real life of factories and adapts to the stages of the journey toward operational excellence.

From standardization to plant management, including the implementation of methodologies and action plans, the mPS provides complete visibility and traceability of daily factory operations. It connects the entire team, from the shop floor to the office, ensuring constant updates.

These are some of the customer success stories we are proud of:

Development of operations model and production system.

Restructuring of Quality Organization in a multi-site environment.

Industrialization of production lines and process approval with OEM´s.

Development of operations model and service delivery system.

Our training programs are supported by the most prestigious training organizations.